Tuck top auto bottom box and tuck top snap bottom box are the most common box structure used in the paper printed packaging. However, it might seem quite complicated to create the dieline for such packaging boxes. Below we illustrate how to create the auto bottom box and snap bottom box.

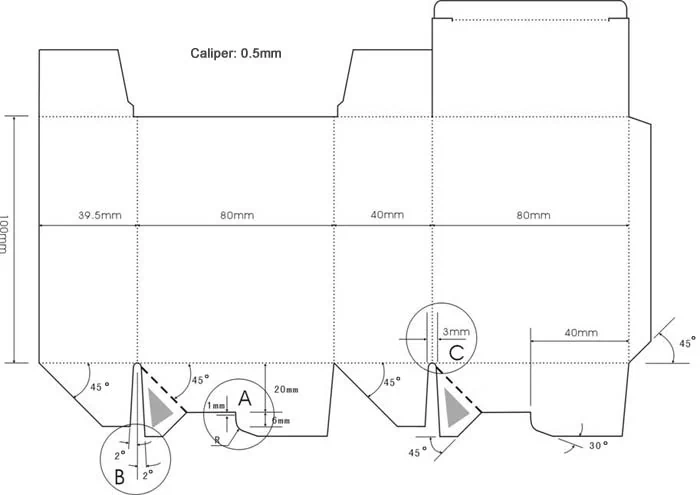

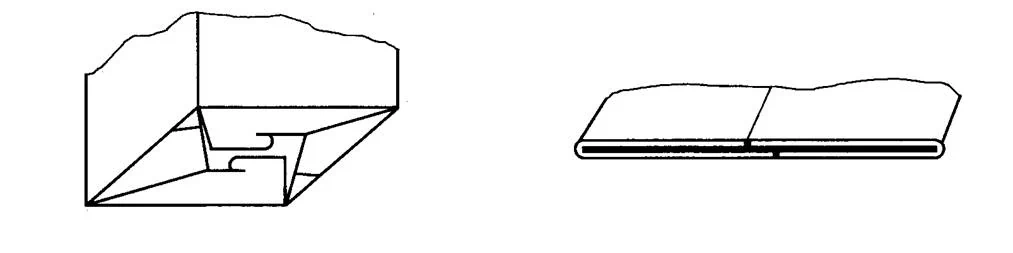

1. Auto Bottom Box

Auto bottom allows for the boxes to be shipped flat and to be quickly assembled on the production line. As for the price, the auto bottom box is a little more expensive than snap lock bottom box.

Auto bottom are widely used in the cosmetic packaging box, custom food packaging, custom retail packaging, custom biotech packaging, custom coffee packaging, custom tea packaging, and custom sporting goods packaging.

The thickness of the paperboard is an important factor when we create the custom paper box dieline. When you need us to supply you a free dieline template, you need to specify the paperboard thickness and inner size of the package. The outer size is working too.

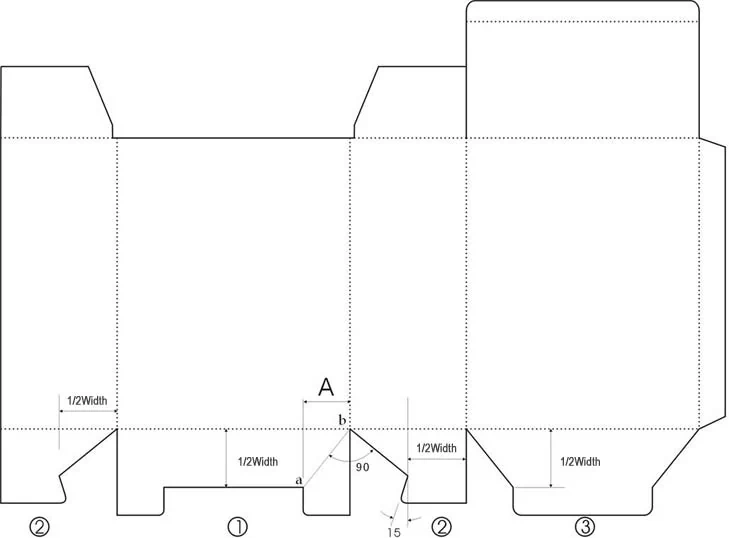

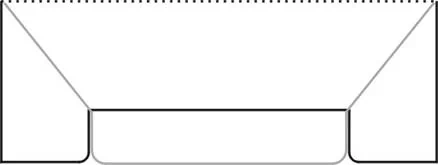

2. Snap Locked Bottom Box

Snap lock bottom are also referred to as 1-2-3 bottom which has four flaps that are folded and locked to form the bottom in 3 steps.It has a stronger bottom compared the auto bottom. It costs less , but takes longer to be assembled.

The bottom structure is simple, aesthetic and costs less with strength and rigidity. Common uses are custom food packaging, retail packaging boxes, electronics packaging cartons, boxes, coffee packaging boxes, tea paper boxes, and custom sporting goods packaging.

As a leading China packaging box supplier, Shanghai DE Printed Box supplies the free dieline template for the auto bottom corrugated boxes, auto bottom printed paper boxes and snap locked bottom corrugated boxes. We have the CAD software system to create the template within a minute. Also, we can provide you the digital sample proofs, 2D or 3D to save you time and costs.