This post is a complete guide for business owners, packaging buyers and marketing directors who need purchase the RIGHT paper bags.

Know your target

When it comes to ordering a paper bag, you need set your target first. This is essential for you to choose the right materials, print design and finish afterwards. Surely you won’t pick the plain kraft paper materials while you want to promote your brand if you own a fancy fashion clothing boutique.

To know your target, just ask yourself this simple question. What funtions would you like the paper bags perform for you?

The paper bag usually has two primary funtions, carrying and marketing. Paper bag help customers carry items easily and conveniently. Also it is a great marketing tool for business owners to increase their brand recognition, which opens new window to oppurtunities.

So which one is your priority?

If you just want to make your customers carry the products easily, it is the strength and durablity that you need focus. It would really be a shame if the wine bottle falls out of the bag and breaks just because the bag is not strong enough. Usually a plain kraft bag would be ok.

However, things will be quite different if you need a high impact paper bag to promote your brand and leave consumers a deep impression. You need take all factors into consideration, including handicraft details, paper materials, rope handles, print design as well the finishes. A little mistake can have a disastrous effect.

Create the Dieline and Print Design Artwork

Let the printer provide an accurate and applicable template

Before you have a print designer create the print design for you, you would better ask your printer if they can create a dieline for you, then you can let the graphic designer put the print design on the template.

In China, most manufacturers are reluctant to provide the free dieline because they scare that you give the order to some other printers after you finish the dieline. They usually will let you put a deposit of 100-200USD and promise to give you 3-5 pieces color printed sample bags after the design is finished. In DE Printed Box, we provide our customers the accurate and applicable template without any charges ahead, because we believe that the good long-term business should be built on the mutual trust.

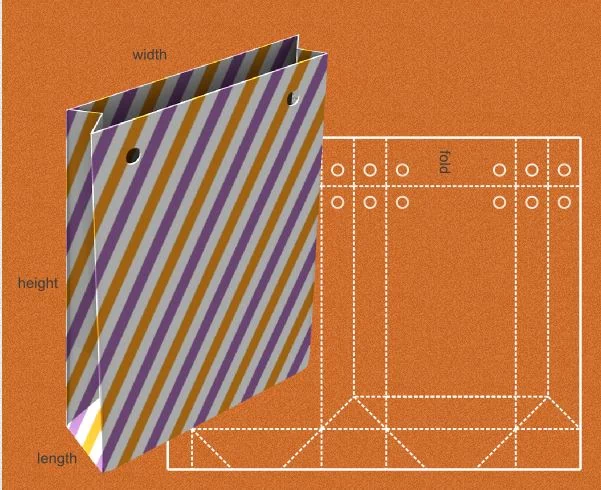

When you let a printer create the template for you, be sure to specify the length, width and height of the paper bag correctly. A mistake in the size specification can lead to frustration and a terrible waste of time for both. In China, the size is usually specified in the order Length x Width x Height, which is illustrated by the image below.

Find a Print designer create the print design

With respect to the print design of the paper bag, knowing the difference between the general graphic design and print design is quite important. Particularly for the long run printing, it may save you tens of thousands of dollars.

The web design adopts the RGB mode while it is CMYK color mode for the printing. A pretty image design created with the RGB mode can have a fantastic display on the computer. However, it may look quite ordinary when printed on the press. It is because the RGB mode has the wider color range than the CMYK color mode. Refer to the post below to learn more about the color space for RGB and CMYK color mode.

Color Space for Human Eyes, CMYK and RGB

In one word, the professional designer knows how to choose the safe colors within the CMYK color space to create the appealing design and how to reduce the costs by using solid colors instead of the process colors. A print designer makes the whole printing process go more smoothly.

When the artwork is finished off, the PDF format is preferred, which represents the most universal adopted standard today.

In addition to the format, be sure to outline all the texts in the artwork in case there is any special fonts involved to create the design. If the printer’s computer lacks this font, the texts will be displayed quite weirdly, which makes the printer’s life quite hard.

About the font issue, some designers may have a different opinion, insisting that a PDF format is enough. And the Adobe Acrobat can display the text quite well even if the text is missing. However, who knows the printing better than the printer? You would better listen to the advice of your printer. Sometimes, an outlined artwork is completely imperative when the artwork is terribly created mixing the print design with the dieline together. It may become the printer’s nightmare when the designer has nothing to provide but a JPEG image with very low resolution.

Choose the Proper Paper Material

Gorgeous paper bag begins with the right paper material that will deliver performance, quality and dependability for the product it holds and carries. Whether it be an exquisite shopping bag with the prominent spot UV varnished logo or a plain brown Kraft food bag, choosing the proper materials is critical to the marketing and visual effect.

How do we choose the proper paper materials?

Paper Types for the Paper Bag

Three types of paperboards are mostly used in the paper bag printing, SBS C1S ( Solid Bleached Sulfate, coated on one side), CUK ( coated unbleached kraft paperboard) and specialty paper.

SBS C1S ( Solid Bleached Sulfate, Coated on One Side)

SBS paper is a coated paper and contains at least 80% natural bleached virgin wood. It has the incredible physical properties, like brightness, whiteness and smoothness to make it very suitable for the high graphics printing of the paper bag. Study suggests that nearly 90% paper shopping bags are made of the SBS C1S paper thanks to its splendid printing quality on the litho offset press. Major industries that use SBS:

- Cosmetic and beauty products packaging bag

- Gift and jewelry bag

- Clothing packaging bag

In Australia, Hong Kong and China mainland, the C1S SBS is often referred to as the ivory board or art paper. And the art paper is slightly different from the ivory board. In the United States and Canada, people prefer to use the term C1S SBS. We will use the term art paper in the description below.

CUK (Coated Unbleached Kraft paperboard)

Also known as the white Kraft paper, it is made of the solid unbleached board coated with a thin layer of kaolin clay, which contains at least 80% natural bleached virgin wood. It is extremely durable and is very suitable to make the heavy duty packaging and carrying bags. Besides, it is very eco-friendly because it is 100% recyclable. The main usages include:

- Frozen food packaging bag

- Heavy duty packaging and carrying

- Beverage carrying bag

Specialty Paper

One typical specialty paper is the black specialty paper with the matte black color. With either silver hot foil stamping or the spot UV varnishing, the paper bag made of this paper looks really gorgeous with a luxurious quality feel. Once before, we helped ProspektSupply in Canada produce a very unique luxury paper bag. We printed the logo (ProspektSupply) in black color and applied the spot UV varnishing on it, which turned out great. Also we use the black specialty paper to produce the paper bag for a well-known bank in China with the silver hot foil stamping for the texts, which looks terrific too.

Besides the black specialty paper, there are actually a lot of types to choose with various patterns and texture.

Paper Grammage and Thickness

Usually the more prestigious the packaging bag, the thicker the paper. Also the grammage and thickness of the paper material have a huge impact on the bag’s endurance.

Usually 157gsm (6-8pt), 210gsm (10-11pt) paper is recommended for the paper bag. And 300gsm (15-17pt) or above art pape can be used when a heavy duty packaging and carrying bag is in need.

The units to represent the paper grammage and thickness are quite confusing. People in China, Australia would like to use the grammage to measure the paper thickness, while the unit pt is used in North America. We have published a post in our blog before to illustrate the conversion between the pt and grams. You can learn more there.

Paper Grammage (gsm) and Thickness (pt) Conversion Table

Select Appropriate Paper Bag Handles

The handle plays an important role in the bag’s performance, aesthetically and functionally. With a good handle, the paper bag can be used for months to a year sometimes thanks to its amazing endurance. There are usually two types of handles are used, the grosgrain ribbon handles and the rope handles.

For rope handles, 3 types of materials are mostly used, the nylon, cotton and the paper. Among these materials, the nylon has the best durability and endurance; the cotton rope handle is the most popular handles used for the paper bag, which has the most wonderful touch in hand; and the paper rope handle can make the paper bag like a piece of great artwork with the help of the top packaging designers.

With respect to the price , the nylon usually costs more than the paper. The cotton handle is the cheapest at around one cents. Generally, the cotton rope are mostly used which has the best hand feel.

Besides, when the paper bag is particularly big, we need use the rivets to fasten the handles to the paper bag.

Apply the Proper Finish

The printing finish adds a luxurious quality feel, turning the ordinary paper bag into an extrodinary artwork.

The laminating makes the paper bag water-proof and more durable. With the glossy laminating, the paper bag will look very shiny, clear and eye-catching. The matte laminating gives the paper bag a very smooth and soft texture, looking more elegant and luxurious.

In the mean time, the spot UV, hot foil stamping, embossing and debossing can also be used to produce an upscale paper bag.

Every finish can have a splendid effect on the paper bag if they are used in the right context. Therefore, each finish is just different but no less at all.

DE Printed Box is a professional paper packaging products manufacturer, which can provide you the best packaging solution with the upscale and luxury feel. Email at janewu@www.deprintedbox.com to learn more.