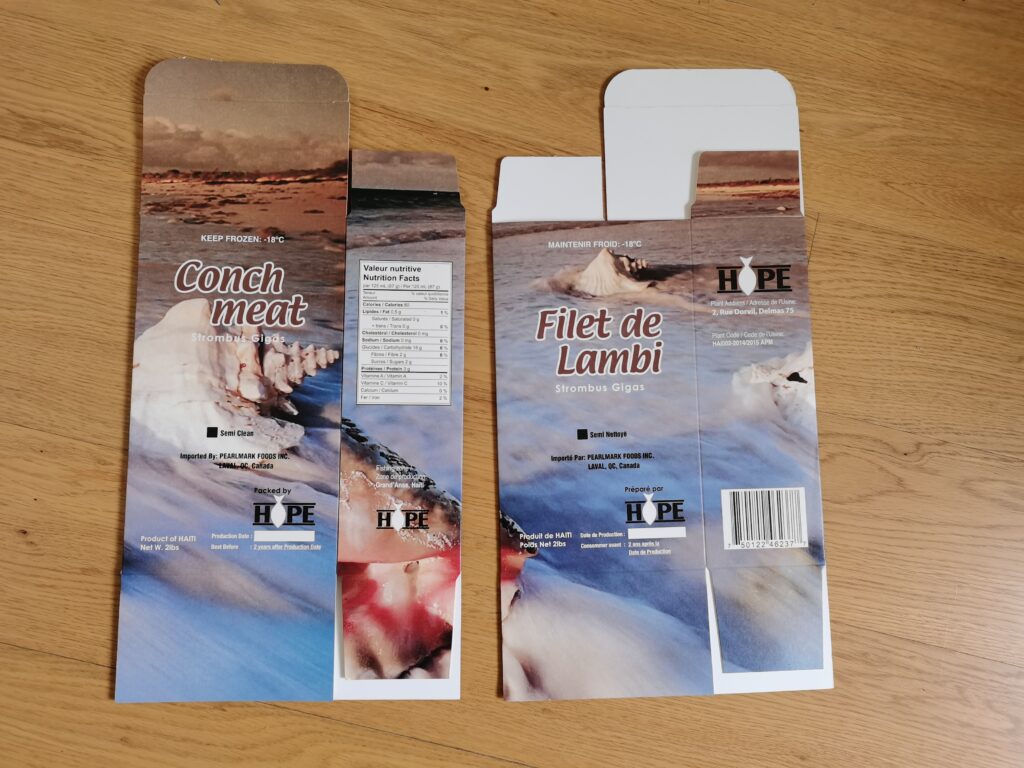

A Heavy Duty Folding Carton With Thin Cardboard

The weak point of a 350gsm folding carton is that it can not carry a heavy item inside. The paperboard is soft and the item is easy to break the bottom and fall down. In this post, we will introduce a heavy duty paper printed box made of the thin cardboard. The folding carton is […]

A Heavy Duty Folding Carton With Thin Cardboard Read More »