M.C. Kaushal1, V.K.Sirohiya2 and R.K.Rathore3

Source: International Journal of Application of Engineering and Technology Vol-2 No.-3

Abstract

Corrugated board is widely used in the packing industry. The main advantages are lightness, recyclability and low cost. This makes the material the best choice to produce containers devoted to the shipping of goods. Furthermore examples of structure design based on corrugated boards can be found in different fields. Structural analysis of paperboard components is a crucial topic in the design of containers. It is required to investigate their strength properties because they have to protect the goods contained from lateral crushing and compression loads due to stacking. However in this paper complete and detailed information are presented.

Keywords: – corrugated boards, recyclability, compression loads, corrugated printed box

1. Introduction

Corrugated board is essentially a paper sandwich consisting of corrugated medium layered between inside and outside linerboard. On the production side, corrugated is a sub-category of the paperboard industry, which is a sub-category of the paper industry, which is a sub-category of the forest products industry. On the marketing side, it is a part of the packaging industry. Throughout the distribution cycle of moving goods from producer to consumer, corrugated is the most widely used kind of shipping container. Traditionally, corrugated is best known for its structural strength that offers protection to packaged products throughout the transportation cycle. However, it has evolved over the course of time and today it is a much more versatile product.

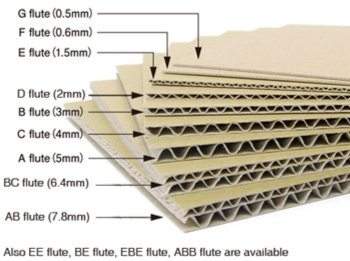

Architects discovered long ago that an arch with the proper curve is the strongest way to span a given space. Corrugated sheets have evolved with this basic principal in mind. The fluted medium is bonded to the liners with a starch adhesive. Once bonded the combined board resists bending. The flutes provide cushioning when pressure is applied from the sides and when placed on end they form rigid columns capable of supporting a great deal of weight. The most commonly used flutes are C and B flute. Others include A, E, and F flute. Specialty micro-flutes have been recently created to form specialized grades capable of competing in the boxboard market. Generally, larger flutes offer greater vertical compression strength and cushioning.

Smaller flutes offer printability advantages as well as structural advantages for retail packaging.

2. History

In 1856 the first known corrugated material was patented for sweatband lining in top hats. During the following four decades other forms of corrugated material were used as packaging material for glass and other products shipped in wooden crates. Then in 1894 the first corrugated printed box was made. However, by 1900 there was a nationwide network of railroads that made it possible to distribute products throughout the nation. At this point corrugated containers were still not a recognized classification by which to ship goods. The term “contained” meant enclosed on all sides in wood. While corrugated lacked the stacking strength of wood it was more affordable, more readily available, lighter weight, more uniform in quality, and more adaptable to volume packing, sealing, and handling. It also offered cushioning and printability advantages. All of these characteristics were attractive to businessmen at that time who were eager to take advantage of nationwide distribution. The corrugated printed box was initially used for packaging glass and pottery containers. Later, the case enabled fruit and produce to be brought from the farm to the retailer without bruising, improving the return to the producers and opening up export markets.

3. Corrugated Cardboard

Corrugated fiberboard is a paper-based material consisting of a fluted corrugated sheet and one or two flat linerboards. It is widely used in the manufacture of corrugated printed boxes and shipping containers.

The corrugated medium and linerboard are made of containerboard, a paper-like material usually over inches (0.25 mm) thick. Paperboard and corrugated fiberboard are sometimes called cardboard; although cardboard might be any heavy paper-pulp based board.

Containerboard, also referred to as CCM (corrugated case material), is a type of paperboard specially manufactured for the production of corrugated board. The term encompasses both linerboard and corrugating medium (or fluting), the two types of paper that make up corrugated board. Since containerboard is made mainly out of natural unbleached wood fibers it is generally brown, although its shade can vary depending on the type of wood, pulping process, recycling rate and impurities content. For certain corrugated printed boxes that demand good presentation white bleached pulp or coating is used on the top ply of the linerboard that goes outside the corrugated printed box.

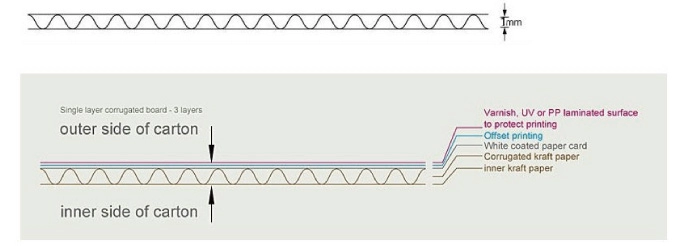

4. Types of corrugated board single face sheet

A corrugated medium with a linerboard facing adhered to one side. It can be manufactured in sheets or rolls. Single face is principally used as a wrapping material, and occasionally for interior packing or padding. Single Wall Corrugated A corrugated medium with a linerboard facing adhered to both sides. It is also referred to as “Double Face”. This popular and versatile 3-ply construction is converted into a wide variety of containers and packaging components.

- Most popular.

- Wide range of strengths.

Double wall corrugated board

Two corrugated mediums with a linerboard facing adhered between them and to both sides. This 5-ply construction is most applicable for packing heavy items where high rigidity and protection is required.

- Made up of B and C Flutes.

- Extra padding and strength.

- Great for stacking heavy items.

Triple wall corrugated board

Three corrugated mediums and four linerboard facings. This 7-ply construction is used where large container sizes are involved, such as pallet packs.

- Made up of two layers of C Flute and one layer of B Flute.

- Very strong and crush resistant.

- Excellent for storage and transit.

5. Raw Materials

The liners and medium that make up the corrugated sheet are both forms of paperboard. Paperboard is made primarily from cellulose fibers found in wood. The fibers are held together by lignin. Fibers are separated from the wood in one of three ways: mechanical, chemical, & semi chemical. Mechanical involves chipping and grinding the wood into increasingly smaller units. Chemical separation, or pulping, uses sulfite or sulfate to dissolve the lignin. This is also known as the Kraft process. This method produces the highest yields with the least damage to fibers, thus the strongest paper. The semi-chem process combines the mechanical and the chemical methods.

Linerboard is the paperboard used as the inner and outer facings of a corrugated sheet. It is made primarily through the chemical process. It is usually made from softwoods like Pine trees that have the longest fibers and produce the strongest board. Medium is the fluted paperboard that is in between the inner and outer facings. It is produced mainly from hardwoods that have shorter fibers through the semi- chem process.

Linerboard and medium are also made from recycled resources. Lumber byproducts like sawdust and wood chips constitute approximately 10% of the fiber supply. Recycled paper provides approximately 25%. The fibers are separated from wood or recovered through recycling processes and cleaned. Liquid paper then flows onto a moving wire screen. Water drains through the wire until it hits the dry line where a paper mat is formed. The paper is cycled through the paper machine where it is further dried, compressed, and wound into large rolls that are shipped to customers that manufacture corrugated sheets.

6. Corrugated Flutes

The inventors of corrugated board applied the same principles to paper as ancient architects did to buildings. When trying to uphold heavy loads, the most efficient way is by using an arch. Generally the larger flute profiles give greater vertical strength and cushioning. The smaller flutes help enhance graphic capabilities while providing greater structural integrity. By experimenting with flute profiles, designers can vary compression strength, cushioning strength and thickness. Flutes come in several standard sizes such as A, B, C, E, and F. Different flute profiles can be combined in one piece of combined board.

| Flute designation | Flutes per foot | Flute thickness (in) | Flutes per meter | Flute thickness (mm) |

|---|---|---|---|---|

| A flute | 33 ± 3 | 3⁄16 | 108 ± 10 | 4.8 |

| B flute | 47 ± 3 | 1⁄8 | 154 ± 10 | 3.2 |

| C flute | 39 ± 3 | 5⁄32 | 128 ± 10 | 4.0 |

| E flute | 90 ± 4 | 1⁄16 | 295 ± 13 | 1.6 |

| F flute | 125 ± 4 | 1⁄32 | 420 ± 13 | 0.8 |

The inventors of corrugated board applied the same principles to paper as ancient architects did to buildings. When trying to uphold heavy loads, the most efficient way is by using an arch. Generally the larger flute profiles give greater vertical strength and cushioning. The smaller flutes help enhance graphic capabilities while providing greater structural integrity. By experimenting with flute profiles, designers can vary compression strength, cushioning strength and thickness. Flutes come in several standard sizes such as A, B, C, E, and F. Different flute profiles can be combined in one piece of combined board.

7. Flute Types

A flute corrugated board

A-Flute, the original flute, is the highest flute size, and therefore, when combined with an inner and outer facing, is the thickest. With 36 flutes to the foot, A-Flute makes the most of corrugated cushioning and stacking properties for fragile and delicate items. Because A-Flute offers excellent stiffness qualities and short column crush resistance, it has application across a broad range of customer uses.

- 36 Flutes / Foot.

- 1/4″.

B flute corrugated board

B-Flute, the second flute size adopted by the corrugated industry, has lower arch heights than A and more flutes per foot (50). This means that the medium contacts and supports the liners at a greater number of points, providing a stiff, flat surface for high quality printing and die cutting and with excellent crush resistant properties. B-Flute is also preferred for high speed, automatic packing lines and for pads, dividers, partitions and other forms of inner packing. Complex die cuts and beverage trays are excellent applications for B-Flute as are can cases, wrap-around blanks, glass-to-glass packs and slipsheets. B-Flute is generally combined with light weight liners but can be used with heavier facings if the need arises.

- 49 Flutes / Foot.

- Good puncture resistance.

- Less space consumed in warehouse.

- Uses: canned goods, displays.

The “Flute” describes the structure of the wave shaped cardboard material that makes up a board’s corrugation. Flutes come in several sizes, known as flute profiles.

Generally, larger flutes provide greater strength and cushioning, while smaller flutes have better printability andfold ability. Flute profiles can be mixed and matched within the same piece of combined board, to manipulate printability, compression strengths, cushioning strengths and the total thickness of the board.

C flute

C-Flute came along next to split the difference between A and B Flutes. With 42 flutes per foot, it’s thinner than A- flute, thicker than B, and offers good cushioning, stacking and printing properties. C-Flute is by far the most widely used flute size. An estimated 80% of today’s corrugated containers are made of C-Flute board.

- 41 Flutes / Foot.

- Good stacking strength.

- Good crushing resistance.

- Very common.

- Uses: glass, furniture, dairy.

E flute

E-Flute has the greatest number of flutes per foot at 94 which gives it the greatest crush resistance and the flattest surface for high quality printing applications. The thin board profile of E-Flute (it is one-fourth the thickness of C- Flute) reduces box size and saves storage space. Because of its thin profile and excellent cushioning properties, E- Flute corrugated box can often substitute for conventional folding cartons or solid fiber containers. Examples of E-Flute applications include boxes for cosmetics, fragile glass and ceramic items and delicate instruments. Another growing end-use is for pizza boxes where the retailer wants a cost effective container with good graphics and excellent product protection.

- 95 Flutes / Foot.

- Light weight.

- Strong alternative to paper board.

- Superior printing surface.

- Excellent for custom die cut boxes.

- Uses: displays, point of purchase boxes.

F flute

F-Flute, the newest flute, is just a little more than half the thickness of E-Flute and is the newest growth segment in the corrugated field. The idea behind the new flute, originally developed in Europe, is to make packages with lower fibre content.

- 128 Flutes / Foot.

- 1/32.

8. Recycling

Recycling is processing used materials (waste) into new products to prevent waste of potentially useful materials, reduce the consumption of fresh raw materials, reduce energy usage, reduce air pollution (from incineration) and water pollution (from land filling) by reducing the need for “conventional” waste disposal, and lower greenhouse gas emissions as compared to virgin production. Recycling is a key component of modern waste reduction and is the third component of the “Reduce, Reuse, and Recycle” waste hierarchy.

Recyclable materials include many kinds of glass, paper, metal, plastic, textiles, and electronics. Although similar in effect, the composting or other reuse of biodegradable waste – such as food or garden waste – is not typically considered recycling. Materials to be recycled are either brought to a collection center or picked up from the curbside, then sorted, cleaned, and reprocessed into new materials bound for manufacturing. Old corrugated containers are an excellent source of fibre for recycling. They can be compressed and baled for cost effective transport. The baled boxes are put in a hydropulper, which is a large vat of warm water for cleaning and processing. The pulp slurry is then used to make new paper and fiber products. Mill and corrugators scrap, or broke, is the cleanest source for recycling. The high rates of post-consumer recycling reflect the efficiency of recycling mills to clean and process the incoming materials. Several technologies are available to sort, screen, filter, and chemically treat the recycled paper. Many extraneous materials are readily removed. Twine, strapping, etc are removed from the hydropulper by a “ragger”. Metal straps and staples can be screened out or removed by a magnet. Film-backed pressure sensitive tape stays intact: the PSA adhesive and the backing are both removed together. Materials which are more difficult to remove include wax coatings on corrugated boxes and “stickies”, soft rubbery particles which can clog the paper maker and contaminate the recycled paper. Stickies can originate from book bindings, hot melt adhesives, PSA adhesives from paper labels, laminating adhesives of reinforced gummed tapes, etc. Corrugated fiberboard shredders are now available which convert post-consumer corrugated board into packing/cushioning materials by means of a specialized shredding process. Recycling corrugated fiberboard helps countries without sustainable wood resources build a paper and packaging industry local.

9. Advantages

The use of corrugated paper packaging made of corrugated cardboard containers, it has many advantages: light weight, structure, good performance. Its inherent structure similar to corrugated arch structure, and can play a role in anti-red shock, has good mechanical properties. Of packaged goods have many good protections. For example, moisture, heat, easy to transport and so on. Transportation costs low and easy to implement packaging and transport mechanization and automation.Changes in specifications and size and easy to implement and can quickly adapt to all kinds of items packaging. Sealing, bundling both convenient and easy automation. Can adapt to all types of cartons decor printing, can be a good solution to the protection and promotion of goods issue.Waste recycling paper boxes easy to meet environmental requirements. Through with a variety of cover material or combination of moisture to expand the scope of its use.

10. Disadvantages

Due to its being readily available, inexpensive and strong relative to its weight, corrugated cardboard is a popular packing material, as well as a popular material for a variety of large-structure arts and crafts products. However, there are times when corrugated cardboard is not the best choice for a project or packing need. Consider some of the disadvantages of this material when you decide if it’s right for your current purposes.

11. Appearance

Corrugated cardboard has an appearance that’s generally less than desirable for craft projects where beauty is a main goal for the finished product. Corrugated cardboard, due to its internal structure, has a rough, ridged appearance over its surface that’s prone to wrinkling and bending. Any structures built from it will have an untidy appearance,

whereas non-corrugated cardboard holds a smooth, neat shape.

STRENGTH

Corrugated cardboard is relatively strong for being so lightweight, but for projects and purposes that need a bit more heft, you may prefer a denser material. Much of the mass of corrugated cardboard is air, due to the shape of the corrugation inside. If placed under much sideways pressure, corrugated cardboard will bend, pucker and crumple.

WATER RESISTANCE

As a packing material, corrugated cardboard provides very little resistance to moisture. When made wet, either from ambient moisture in the environment or from direct contact, corrugated cardboard will soften, eventually becoming pulpy. Corrugated cardboard is also highly absorbent, and will thus readily transfer moisture to its contents.

EDGES

Due to the layered construction of corrugated cardboard, cutting any kind of intricate or curved shape from a sheet of this material is likely to yield untidy-looking results. The corrugated inner layer will often show on the edge of a cut.

FOLDING

It’s difficult to create neat folds in corrugated cardboard. The inner layers will both dictate the shape of the folds (not necessarily in the direction you want) and cause the material to stretch and crumple in unintended (and undesirable) ways.

BULK

While the curvy, air-filled corrugation inside the layers of the cardboard provide excellent cushioning, their bulk makes them inconvenient for many craft projects or structures that might require more detail and finesse in shaping. The thickness of cardboard, relative to the structural strength it provides, is sometimes a disappointment for such designs.

CUTTING

When cutting a piece of corrugated cardboard into a certain shape, it can be difficult to get the angle just right so as to make a clean cut through both the two outer layers and the inner corrugated layer. Without an even cut with a blade positioned at a consistent 90-degree angle to the cardboard, the cut will angle, making the two sides different sizes.

12. Conclusion

The main of this paper to provide information regarding corrugated cardboard such as sheet, flute, weight, appearance etc. This will help for analyzing the corrugated cardboard with different and environment condition. And then complete analysis will help in the development of corrugated cardboard structure.

13. Reference

- Cristina Gentilini, Lucio Nobile, Keith A. Seffen “Numerical analysis of morphing corrugated plates” Procedia Engineering 1 (2009) 79–82.

- L.X. Peng, K.M. Liew, S. Kitipornchai “Analysis of stiffened corrugated plates based on the FSDT via the mesh-free method” International Journal of Mechanical Sciences 49 (2007) 364–378.

- K.M. Liew, L.X. Peng, S. Kitipornchai “Nonlinear analysis of corrugated plates using a FSDTand a meshfree method” Comput. Methods Appl. Mech. Engrg. 196 (2007) 2358–2376.

- S. Allaoui, Z. Aboura, M.L. Benzeggagh “Effects of the environmental conditions on the mechanical behavior of the corrugated cardboard” Composites Science and Technology 69 (2009) 104–110.

- Wan-Shu Chang, Edward Ventsel, Ted Krauthammer, Joby John “Bending behavior of corrugated-core sandwich plates” Composite Structures 70 (2005) 81–89.

- M.E. Biancolini “Evaluation of equivalent stiffness properties of corrugated board” Composite Structures 69 (2005) 322–328.

- N. Talbi, A. Batti, R. Ayad, Y.Q. Guo “An analytical homogenization model for finite element modeling of corrugated cardboard” Composite Structures 88 (2009) 280–289.

- P. Isaksson, P. Gradin “Shear buckling in the core of a corrugated board structure” Composite Structures 88 (2009) 610–614.

- Y.S. Tian, T.J. Lu “Optimal design of compression corrugated panels” Thin-Walled Structures 43 (2005) 477–498.

- G. Pitarresi, J.J. Carruthers, A.M. Robinson, G. Torre, J.M. Kenny, S. Ingleton, O. Velecela, M.S. Found “A comparative evaluation of crashworthycomposite sandwich structures” Composite Structures 78 (2007) 34–44.

- Sai Sudha Ramesh, C.M. Wang, J.N. Reddy, K.K. Ang “A higher-order plate element for accurate prediction of interlaminar stresses in laminated composite plates” Composite Structures 91 (2009) 337–357.

- G. Kress, M. Winkler “Corrugated laminate homogenization model” Composite Structures 92 (2010) 795–810.

- Jack Reany, Joachim L. Grenestedt “Corrugated skin in a foam core sandwich panel” Composite Structures 89 (2009) 345–355.

- M. Winkler, G. Kress “Deformation limits for corrugated cross-ply laminates” Composite Structures 92 (2010) 1458–1468.

- Y. Wang, J. Weissmüller, H.L. Duan “Mechanics of corrugated surfaces” Journal of the Mechanics and Physics of Solids accepted date 12 July 2010.