How to Convert ECT in Pound Per Inch to Newton per Meter?

When are choosing the corrugated board to make a RSC style shipping carton, the carton box strength is an important factor we need to consider. Then our corrugated printed box can protect the goods well without breaking apart during the shipment and storage. And it stays in good condition when it finally arrive in the retail store.

Edge Crush Test 瓦楞纸板边压强度测试

在瓦楞纸板的边压强度测试过程中,实验人员首先认真仔细阅读边压强度测试仪器的使用说明;

然后根据说明要求,用锋利的美工刀裁取瓦楞纸箱上面3片无机械压痕、无印刷痕迹和损坏的规整的长方形纸板。纸板顺瓦楞方向高度一般为2.5-4cm, 瓦楞横切方向长度一般为5cm,或者10cm.

接着,实验人员打开实验仪器,将裁切的瓦楞纸板顺瓦楞方向置于抗压强度测试仪上下压板之间,并用两只导块夹住,两头平齐(如上图);

样品放置停当后,实验人员按仪器开始测试键,观察记录瓦楞纸板样品被压垮时的显示屏数据;

最后,实验人员对其余两片样片采用同样的方法测试记录数据,最后取平均值。

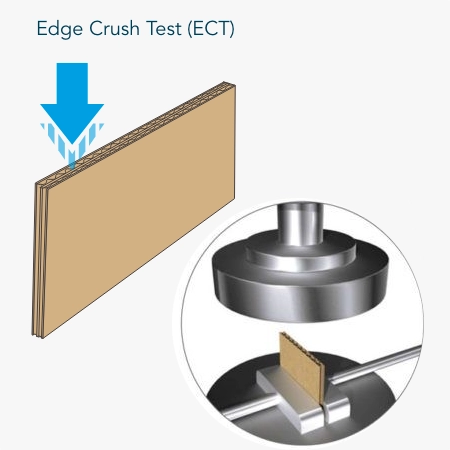

An edge crush test (ECT) is a laboratory test method used to measure the cross-section crushing of corrugated cardboard. This offers the necessary information to determine the ability of a sheet of corrugated cardboard to resist crushing forces.

When performing an edge crush test, a cross-sectional load is applied on corrugated cardboard until it collapses, thereby calculating the maximum compression force that the material can withstand without failing.

ECT Unit in LBS PER INCH

The edge crush test machine can calculate the resistance to compression at the edge of corrugated cardboard. Therefore, this test shows the resistance in pounds per lineal inch (lb/in), though it is usually expressed as ECT.

ECT is a measure of the edgewise compressive strength of corrugated board. It is measured by compressing a predefined section of board on its edge between two rigid platens. This compression is performed perpendicularly to the direction of the flutes until the board collapses and a peak load is reached.

ECT Conversion to NEWTON PER METER

This load is reported as force per unit width (lb/in, kN/m, etc). When reported as an ECT value (eg 44 ECT) this relates to a minimum strength value and corresponds to pounds per inch width (lb/in).

欧美通用的边压测试强度单位是lbs/inch, 即为磅/英寸。国内的瓦楞纸板边压测试仪器显示结果为:牛/米。两个单位直接存在一定的换算关系。详细如下:

ECT 1 磅/英寸 = 175 牛/米

ECT 32 = 32*175 = 5600 牛/米

ECT 44 = 44*175 = 7700 牛/米

lbs is the unit of mass used in Britain and USA.

1 lbs = 0.45359237 kg

Inch is the unit of length used in USA.

1 inch = 0.0254 meter

If we need to convert ECT 1 in lbs/inch to Newton/meter, then we can do the calculation below:

1 * 0.45359237 * 9.8 / 0.0254 =175 N/m

For ECT 44, that is 44*175 = 7700 N/m

For ECT 32, that is 32*175 = 5600 N/m

Advantages of ECT Packaging

This test is a useful tool both for cardboard manufacturers wishing to perform quality control, and for corrugated box manufacturers looking to test the protective ability of their raw material. By using simple test methods such as the Edge Crush Test (ECT), companies benefit from understanding the maximum weight a corrugated box can withstand and the overall stacking strength. All of this also leads to lower energy consumption and less pollution across all phases of the packaging cycle.

The first advantage of ECT packaging is that an ECT box offers greater safety to transported goods since the level of protection offered by it during the distribution cycle has been calculated.

Furthermore, in addition to offering an exact value for the material’s resistance, ECT packaging allows for the use of fewer materials. This is because, by performing the test, it is possible to determine the exact amount of corrugated cardboard that will ensure the goods’ protection, thereby optimizing the packaging.

ECT gives a good picture of overall strength, enabling cardboard and box manufacturers to better maintain and improve quality control testing, during formulation, processing and production

Since the edges and corners of a box are mostly responsible for bearing the load, it gives a good picture of material strength allowing cardboard manufacturers to perform quality control, and corrugated box manufacturers to select the most appropriate materials and processes to produce their protective packaging.

How to test ECT by the EDGE CRUSH TESTER

HD A513B (ECT) Edge Crush Tester

Specimen size: 25*100mm corrugated board

Specimen preparation: At least 10 sample pcs sample corrugated board

Temperature: at 23°and Relative humidity: with 50%。

Put on the gloves, switch on the power supply, turn on the power switch and enter the task status after self inspection.

Click enter test and enter the password 000000 to enter the test interface.

Click SET to enter interface,and select the test type as EDGE CRUSH, then enter the sample length 100MM,click TEST INTERFACE to return to start testing.

Pull the specimen on the center of down-pressure plate,make sample short edge perpendicular to the up and down pressure plate, reoccupy lead guide block clamping sample, make specimen and two vertical pressure plate, click on the down button to adjust the pressure plate until close to the location of the specimen.

Click zero, click test button to start the test automatically.

When the test sample is crushed, the test is completed automatically and the task results are automatically retained. The up pressure plate is automatically returned to the original position and the specimen is taken out and observed.

After the test is completed, the machine will automatically save the data and click open to view the current and accumulated test results report.