In this post, we will introduce a few corrugated carton boxes with partitions. Below are the specifications required by the client.

PART ONE – CORRUGATED BOXES

Materials

We would preferably like to have the recycled fibers for the corrugated board. Otherwise, virgin fibers are an alternative if they are the only way to deliver the minimum required mechanical properties.

Total Carton Weight

Each corrugated carton box should not exceed 25 lbs once filled with products.

Carton Content

The products will be sent to different countries. The shipping cartons will be varied by the export countries.

TRADE products for USA must be bundled by 3, then 4 bundles must be placed in each corrugated printed box.

TRADE products for other countries can be packed unbundled in corrugated cartons (no need for bundles of 3, not need for a given number of 12 units per carton box).

Corrugated Box Dimensions

Shipping carton dimensions must be preferably selected so that it allows an efficient pallet pattern on US (40”x48”) pallets and/or European (800x1200mm) pallets.

Ideally also, if the corrugated shipping boxes allow pallet patterns with interlocked layers, this is a preferable choice.”

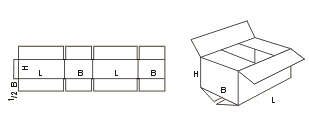

Corrugated Carton Dieline

Regular Slotted Container (RSC), as per FEFCO definition.

Standard corrugated carton box with the most common closing of lids – with a wide range of applications. Option for cases with full color plus solid pantone color prints, 3- or 5-layer cardboard, brown or white cover.

Mechanical properties

For shipping cartons dedicated to products packed in individual cartons or trays:

| Corrugated Board Flute Type | BC flute corrugated box |

| Resistance to Edge Crush Test (ECT) | Minimum 29 lbs per inch / Recommended 32 lbs per inch |

| Resistance to Bursting Strength Test (Müllen) | Minimum 175 lbs per square inch / Recommended 200 lbs per |

For shipping cartons or boxes dedicated to TRADE products packed without individual cartons, without trays:

| Corrugated Board Flute Type | C flute corrugated box |

| Resistance to Edge Crush Test (ECT) | Minimum 26 lbs per inch / Recommended 29 lbs per inch |

| Resistance to Bursting Strength Test (Müllen) | Minimum 150 lbs per square inch / Recommended 175 lbs per |

For shipping cartons or corrugated boxes dedicated to TRAVEL/TRIAL/SAMPLE formats packed without individual cartons or without trays:

| Corrugated Board Flute Type | E flute corrugated box |

| Resistance to Edge Crush Test (ECT) | Minimum 26 lbs per inch / Recommended 29 lbs per inch |

| Resistance to Bursting Strength Test (Müllen) | Minimum 150 lbs per square inch / Recommended 175 lbs per |

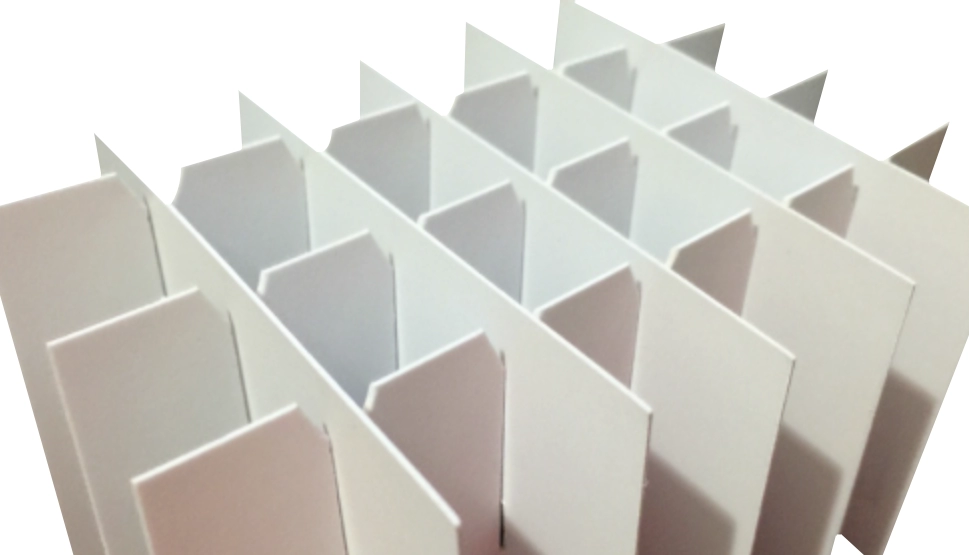

PART TWO – PARTITIONS

Scope and Application

The partitions are required for TRADE products when tye are not individually packed in folding carton, tray and when not bundled by 3.

Partition Materials

SBS carton board, coated on its two sides (C2S). It can be clay coated or made of milk board also coated on both sides.

Clay coat is more expensive than chipboard. But it provides a clean and aesthetically pleasing look while being a great choice for protecting cosmetics and pharmaceuticals.

Milk board is coated on both sides, providing all-around protection from spills, breaks, and scratches on our products. It is FDA approved for direct contact with the food products themselves.

Do not use coating made of any plastic or resin (PE, PU…).

Thickness

0.018” (18pts) to 0.024” (24pts).

Partition Structure

As per this example; each cavity should be surrounded with partition walls.