What is CTP?

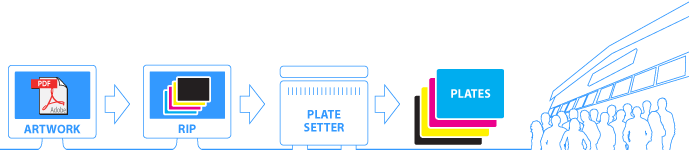

In the traditional Offset printing process of custom paper box, the print design is output to the photographic film first, then the printing plate(mainly PS plate) is made. Therefore, this imaging technology is also referred to as CTF, computer to film. However, things are quite different now. In the modern printing facility, the artwork, usually in the PDF format created by the Adobe Photoshop, Adobe Illustrator, Adobe Indsign and other desktop layout applications is output directly onto the printing plate. And this tech is called CTP.

CTP Technology

CTP tech varies with the construction type of the imagesetter and the light source used to expose the plate surface. In terms of imagesetter, there are three different kinds: internal drum, external drum and flat-bed imagesetters. And the light used to expose the printing plate are mainly ultraviolet light lamps and laser diodes. The wavelength and energy of the laser diodes depend on used plate types.

CTP Plate Category

There are mainly 3 types: Photopolymer CTP plates, Silver Halogan CTP plates, and Thermal plates.

Advantages of the CTP Plate

CTP has several advantages over conventional platemaking. In CTP, one generation (transfer of film image to the printing plate) is removed from the printing process (eliminating the need for film and related developer chemicals), increasing sharpness and detail. CTP avoids potential losses in quality that may occur during film processing, including scratches in the film, and variations in the exposure. An imagesetter usually has an accuracy rate of +/-2%. Plates are produced in less time, are more consistent, and at a lower cost. CTP can also improve registration and image-to-edge repeatability over traditional methods.

In CTP, the media is registered (held in precise position) in the platesetter during imaging, and does not rely on a separately-aligned pin grid, as is the case with film. Defects due to dust, scratches or other artifacts are minimized.

CTP systems can significantly increase plate production outputs. Platesetters for newspaper production can output up to 300 12-inch (300 mm) plates per hour at 1270 DPI (dots per inch), whilst for commercial applications a CTP system could output 60 B1 plates at 2400 DPI for higher screen rulings.

Small portrait presses that typically create 1 or 2 color output can use anything from a standard laser printer, for low quality/low volume, up to a higher-end dedicated platesetter for higher quality and volume.

Disadvantage of the CTP Plate

Restricted to digital format. CTP productions require that the basis for the printed matter as well as the imposition, be digital.

Remaking of plates. If for some reason a CTP plate is damaged, if an error occurs when it’s ripped or if something has to be corrected after the plate is exposed, a completely new, imposed plate must be created

The CTP Tech in Deprintedbox

Deprintedbox uses the latest Computer to Plate technology, saving both time and money and improving print quality.

Faster Production Cycles CTP eliminates steps from the production cycle. Even in a Computer to Film (CTF) workflow it can take five steps from having the copy in digital form to having it imaged on a plate. In a CTP process four of these steps are fully removed. Each step eliminated from the process reduces the overall time required to get plates to press, getting the job to you more quickly.

Lower Printing Costs CTP eliminates the need for film by imaging the page directly from the computer to the printing plate, which, shortens production cycles and can save on material costs ultimately saving you money.

Sharper Print Quality CTP allows printing presses to print cleaner and crisper images by way of eliminating dot gain in the prepress process. In a CTP workflow, first generation dots are imaged to the plate eliminating dot gain in prepress. This gives the press more capacity for printing higher ink densities resulting in richer, better saturated colours.

Better Registration CTP excludes the use of film negatives or positives. CTP plates are imaged on highly accurate plate setting equipment on aluminium substrates that are very resistant to changes in temperature and humidity. Even imposed computer to film workflows cannot offer the accuracy and stability of registration that a CTP system can provide.

Shanghai DE Printed Box is a China medium-sized custom paper box manufacturer and packaging solution provider with facilities around 100,000 square meters in total. The company exclusively specializes in the supply and export of the custom paper boxes, including the paper printed box, corrugated printed box, cosmetic paper box, rigid paper box, cardboard gift box and custom paper bag. If you have any questions about the custom paper box, or would like us to give you a price quote, please do not hesitate to contact us by giving us an email.