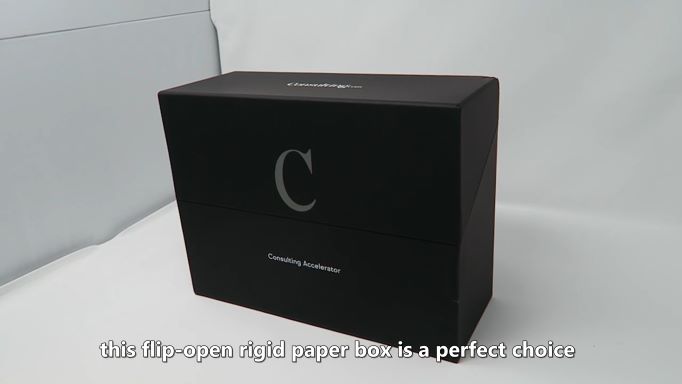

Some Bespoke Paper Boxes For Packaging

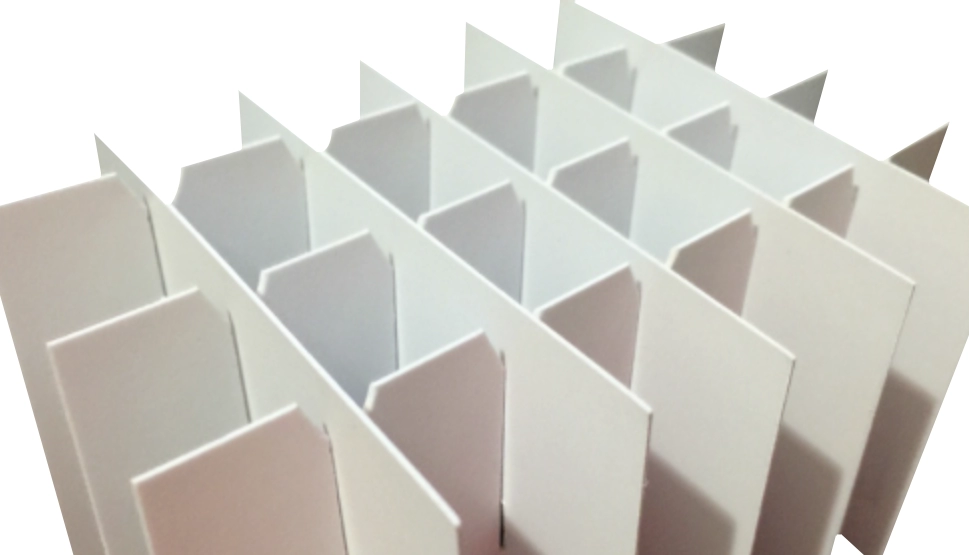

A bespoke paper box is a premium quality packaing with the custom size, color, paper material and style. Shanghai DE Printed Box supplies all kinds of custom paper boxes as per the request of the client. In this post, we will introduce 3 bespoke paper boxes. Corrugated Box For Knife Packaging This is a corrugated […]

Some Bespoke Paper Boxes For Packaging Read More »