Three Methods to Add the Metallic Finish

The metallic gold/silver finish is a great way to add the impressive and luxury quality feel to the cosmetic packaging box. In practice, there are usually 3 methods to create the metallic look on the paper box. They are foil stamping, metallic ink printing and metalized paperboard printing.

Foil stamping

Foil stamping has 2 categories, hot foil stamping and cold foil.

Hot Foil Stamping

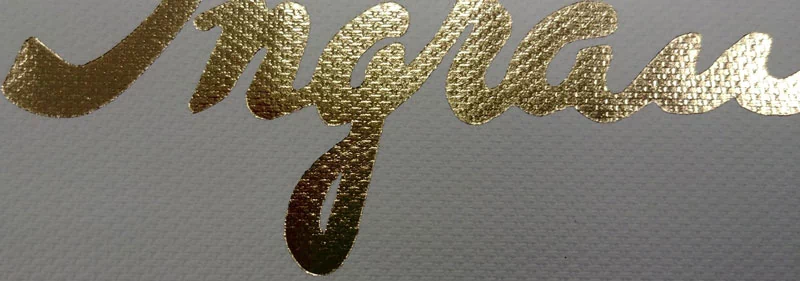

The application of the hot stamping foil has a very long history. It is among the oldest known methods of creating a metallic finish and among the most advanced in technical development. The metallic finish is created by transferring a very thin layer of aluminum coating on the foil paper to the intended paperboard by using heat and pressure. The heat activates separation coatings and adhesive coatings that affect the permanence of the resulting finish on the paper box. The process is typically performed after the sheet-fed offset printing, but can be done prior to the printing if the application equipment has great precision. Under proper conditions, this method can create a broad range of shiny areas, from large solids to very fine details.

Cold Foil

Cold foil has been growing dramatically recently both in brand owner use and in technical development. The process is much the same to that of transfer metalizing described later, with the exception that the application of the metal effect is typically performed during the printing process when the paperboard is printed. A roll of vacuum metalized polyester film which has a separation coating and a surface protection coating is used to provide the metallic finish. This film is placed in contact with the sheet between printing stations following the application of an adhesive. The metallic coatings from the film will only transfer to the paper sheet where the adhesive has been applied. The adhesive is cured to set the metallic look with permanence to the sheet so that additional colors of ink can be applied directly to the metallic surface. With regard to the metallic effect, the cold foil can not rival the hot foil stamping at present.

Metallic Inks Printing

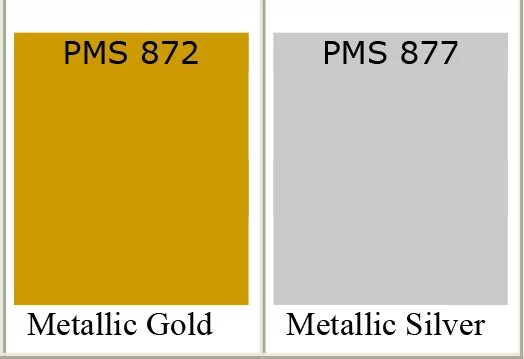

Two types of technology are widely used to produce metallic inks and coatings. Of the two, the oldest technology dates back several decades and has traditionally been referred to as metallic powder technology. The finished results of products using metallic powder suffered from a number of shortcomings. Reflectivity and brilliance was dull at best and resistance levels to in-use exposures were often a risk. The latest technology for metallic inks and coatings is referred to as metal platelet technology. Metal platelet technology has significantly overcome the shortcomings of the metal powder technology. Metallic PMS Printing uses the metallic inks to print a unique shiny appearance. Unlike the common PMS inks, the metallic inks are mixed with the metallic particles, which is usually made of the copper, aluminum, bronze or zinc. When the metallic ink is printed and left to dry, the metallic particles rise to the surface and create a metallic sheen.

Metalized Paperboard Printing

The metallic effect of this method is realized by the natural metallic color of the metalized paperboard. When the designer creates the layout, the area which are intended to have the metallic finish are left transparent. During the printing process, the CMYK inks are only printed on the text area and the colored area. While the transparent area on the artwork has no inks applied on the metalized paperboard. Generally, there are 4 kinds of metalized paperboard used. The metalized paperboard can be glossy or matte.

Aluminum Foil Board Laminates

Foil board laminates were among the first type of processes for creating a metallic look on paperboard. This product is produced by physically laminating with an adhesive – a sheet of aluminum to a sheet of paper. The manufacturing process is very efficient, however there are relatively few companies involved in the production of aluminum foil board globally. The finished product usually has the higher grammage value than other metallic decorating alternatives.

PET/BOPP-Metalized Paperboard

The product is produced by metalizing the PET or BOPP film of choice and laminating the metalized film to the paperboard with an adhesive.

Transfer Metalized Paperboard

Transfer metalized film is produced to create a metalized surface on thinner caliper papers and when weight reduction in an application is desired. The manufacturing process is similar to cold foil transfer processes, but on a larger high-volume scale. A film is coated and metalized to allow the layer of aluminum metalizing to be released away. This metalized film is placed in contact with a paper or paperboard that has an adhesive applied to it. The adhesive can be applied in a flood manner, covering all of the sheet, or a discrete manner, allowing selective elements to transfer. The paper and the film is then stripped away releasing the metallic aluminum, which remains on the sheet only where the adhesive has been applied. The finished product is among the lightest weight options for metallic finishes.

Direct Metalized Paperboard

Direct metalized boards and papers are typically produced using vacuum metallization which deposits a very thin vapor of aluminum directly onto the coated paperboard. The resulting aluminum layer will take on the attributes of the paper fibers or surface profile. Very smooth papers will provide higher reflectivity than less smooth papers. Direct metalized papers and boards are most commonly coated with a clear coating. The coating will provide attributes for printing, exposure resistance features and final finish to the paper. The coatings can be cellulose-based or acrylic-based. Application methods will cure using oxidation, ultraviolet light or electron beam. It is one of the lightest weight options.

Difference between the Foil Stamping and the Metallic Inks Printing

The debate over foil stamping versus Metallic PMS printing has been lasting for a long time. It comes down to what elements you want to give the metallic finish to and the effect you’d like to achieve. Both techniques have their downsides, but both methods also have aspects in which they excel over the other.

Shiniest Finish – Foil Stamping

Foil stamping provides a more realistic metallic finish over PMS spot printing because it is the last thing to be applied to your packaging box. Due to the runny nature of metallic inks, they have to be put down first during the printing process. Each time you add new ink to the material (on top of the metallic ink), the effect may become muddled.

Best Subtle Metallic Effect – Metallic PMS Ink

If you need a more subtle metallic effect, then metallic ink is a much better choice over foil stamping. You could make a metallic ink the most prominent color in a presentation folder for a very effective design; however, you couldn’t foil stamp the majority of a folder without it looking gaudy and overdone.

Best Choice for Embossing – Foil Stamping

If you want to add a metallic shine to embossed elements, then your only choice is foil stamping. This is due to the nature of metallic PMS ink, which has real flecks of metal inside the mixture. If metallic ink were to become embossed, the ink would crack and the effect would be ruined. Metallic foil sticks perfectly to embossed elements, drawing attention to them.

Biggest Color Variety – Metallic PMS Ink

Both foil stamping and metallic PMS inks offer a wide range of colors that resemble real metals, such as gold, silver and bronze. They both also have a number of tinted metal colors in reds, blues and greens. However, since metallic PMS ink is a mixture, it can be altered to many different degrees, allowing for a wider range of colors to select from.

Since metallic ink is applied during the printing process, it is a more cost effective way to add a metallic effect to your marketing materials.

Most Durable – Foil Stamping

The metal particles in metallic PMS ink can cause it to become brittle over time. This has the potential to leave your marketing materials with a cracked ink effect when they start to get old. Metallic ink requires a coating on top to make it last longer. Foil has a much longer lifespan which is actually lengthened if the foil elements are debossed, because it creates a better seal onto the stock.

Least Expensive Option – Metallic PMS Ink

Metallic PMS ink is generally the most cost effective way to add metallic elements to your printed materials. On average, an area that is spot printed using ink will be less expensive than foil stamping an area of the same size.

Most Stock Options – Draw

The battle of metallic foil vs. metallic ink is basically a stalemate when it comes to the ability to choose a variety of stocks. Both techniques are particular and they won’t necessarily get along with every stock option. Foil stamping works on most paper options, but it doesn’t stick well to textured stocks like linens. Metallic PMS ink looks its best on glossy paper; however, it can also look subtly stunning on matte as well. It can also look too bright on white colored stock and like foil stamping, it doesn’t print well on textured stocks either.

Foil stamping provides a textural relief that can be felt with your fingertips.

Best for Fine Detail – Metallic PMS Ink

Since metallic PMS ink is printed like any other ink, it can retain a greater level of detail over foil stamping. Anything you have foil stamped must be cut out from a foil stock, which means that small details can be hard to reproduce without compromising the integrity of the foil.

Best Textural Effect – Foil Stamping

Since metallic foil is a separate element that is applied last, it has a textural quality that can be felt by the hand. Foil is smooth to the touch, like actual metal and is noticeably different from the stock used in your marketing products. This effect is heightened even greater when foil designs are also embossed.

The Conclusion

There isn’t an easy winner in the debate between foil stamping versus metallic PMS ink because it’s like comparing apples to oranges. Foil stamping is the best choice for drawing attention to your smaller elements like embossed logos and text, but metallic ink is best when you want to incorporate a metallic sheen into your large scale design elements. Both offer a different quality, and both can be just as effective at making your marketing materials appear strong and authoritative.

Shanghai DE Printed Box is a China medium-sized custom paper box manufacturer and packaging solution provider with facilities around 100,000 square meters in total. The company exclusively specializes in the supply and export of the custom paper boxes, including the paper printed box, corrugated printed box, cosmetic paper box, rigid paper box, cardboard gift box and custom paper bag. If you have any questions about the custom paper box, or would like us to give you a price quote, please do not hesitate to contact us by giving us an email.